Article

閉じる

Search

Achieving Copper-like Conductivity, Thick Film Formation, and Low-Temperature Processing

Oxidation Resistance:

Excellent oxidation resistance

allows it to withstand solder

reflow processes.

Low-temperature Wiring:

Formation on Polyimide

Resin Substrates

Thick Film Formation

with Proprietary Low-Temperature Sintering

Copper Powder in Metal

Complex Ink

High Conductivity

Achieved Through Sintering, Close to Copper metal

Sumitomo Metal Mining's MOD paste (Metal Organic Decomposition Paste) is developed as a material for printed electronics, the next-generation circuit formation technology. It features high conductivity close to that of copper metal, low temperature sinterability, and oxidation resistance. By using the MOD ink and Sumitomo Metal Mining's low-temperature sinterable fine copper powder, it allows flexible film thickness control from thin to thick films, making it applicable for a wide range of devices from compact and lightweight to large-area devices.

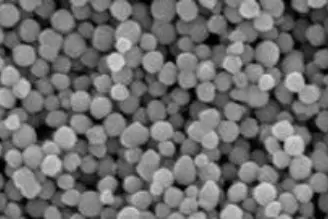

The fundamental construction combines fine copper powder, which sinters at temperatures around 200°C, with MOD ink as the base for MOD Paste. MOD ink basically consists of Copper (Cu) and Nickel (Ni) complex liquid. By using this MOD ink, MOD paste could have low temperature sinter ability and highly oxidation resistance.

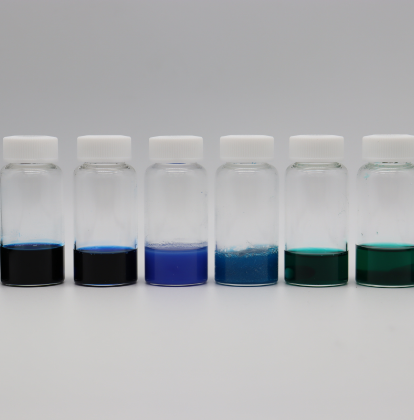

MOD Paste and MOD ink (Metal Organic Decomposition ink) as the Base for MOD Paste

Achieving process simplification and environmentally friendly circuit formation by reducing energy consumption and improving film thickness during printing.

The metal complex conductive paste is a conductive material for printed electronics that enables low-temperature sintering, primarily using metal complex ink and copper powder.

Printed electronics is a next-generation technology that forms electronic circuits by printing metal films only where needed. Conventional inks using silver or copper nanoparticles are expensive and limited in application due to design restrictions like oxidation reliability and thin film thickness.

Our conductive paste overcomes these challenges by combining metal MOD ink with low-temperature sinterable fine copper powder and nickel for oxidation resistance, achieving an ink capable of forming thick films that boast high conductivity, suitable for large-area and high-current applications.

Material:Fine Copper Powders

For more details, please download our materials on MOD paste.

For conductive material as Printed Electronics

MOD Paste is considered for a variety of uses, reflecting its wide range of potential applications.

The following applications are expected:

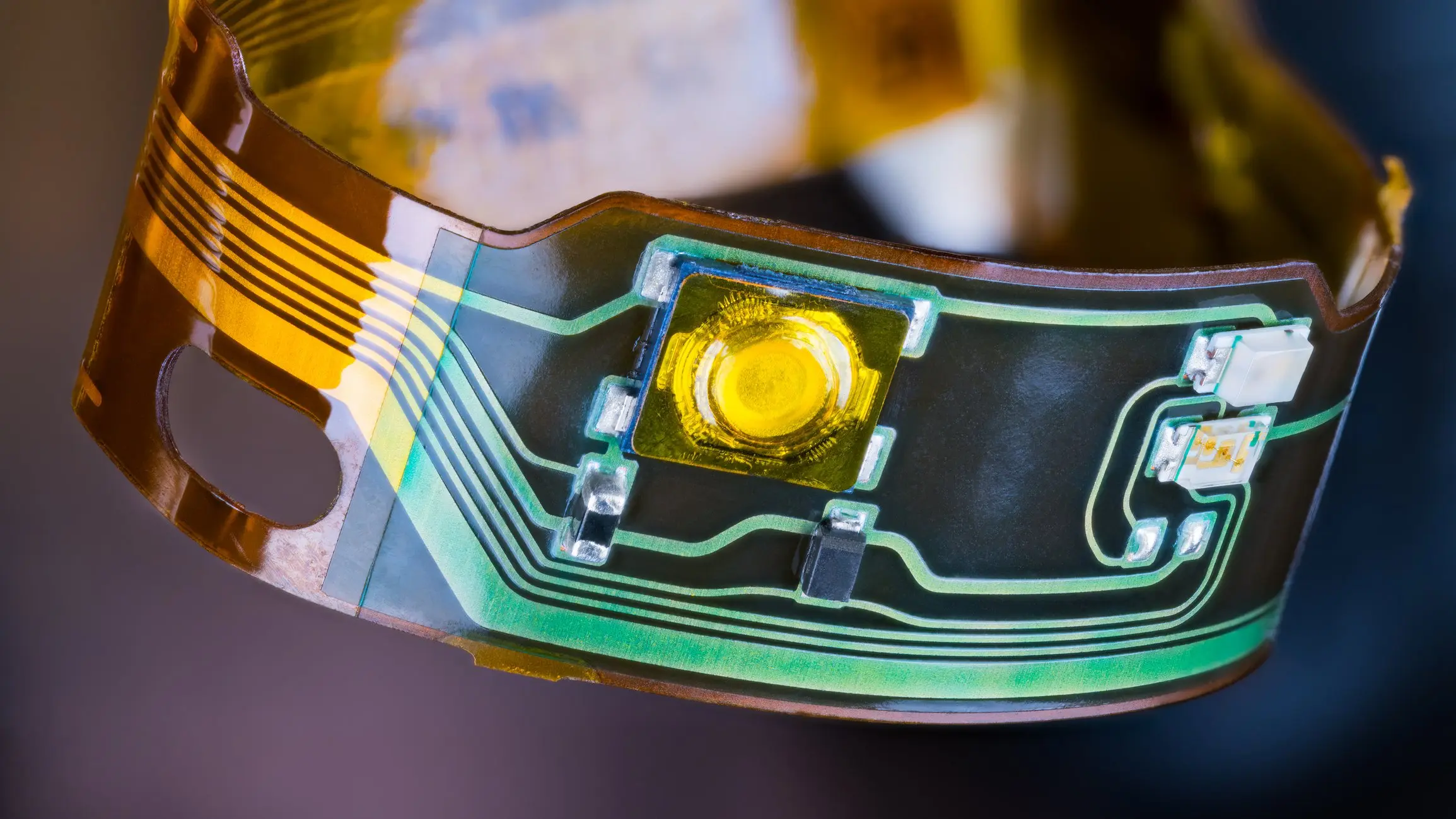

The superior low-temperature sinterability of the MOD Paste finds application in key technologies for realizing an IoT society. Unlike traditional subtractive methods that involve etching, printed electronics use an additive process, applying conductive ink/paste only where needed, reducing material usage, environmental impact, and manufacturing costs. This paste is suitable for thin, lightweight, and flexible electronic devices, applicable in automotive wiring, solar cells, wearable devices, sensor devices, RFID tags, and more.

Our dialogue content “X-TALK” features discussions with guests from inside and outside the company, including articles on the future of printed electronics.

Copper circuits with oxidation resistance

on transparent polyimide substrates

Copper circuits with oxidation resistance

on polyimide substrates

Example: Oxidation-resistant copper circuits on transparent polyimide substrates achieve over 30 micrometers in thickness, compared to the usual 10 micrometers of metal complex ink without added copper powder.

ombining Sumitomo Metal Mining’s expertise with industry insights, X-MINING is here to innovate and solve challenges.

If you see potential, don’t hesitate to reach out with any questions you may have!

Article

Article

Article

X-TALK

Case

Article

Introducing Sumitomo Metal Mining’s material products,

which are the starting point for X-MINING innovation.