In today’s rapidly changing society, industries face evolving demands such as DX and

cabon neutrality, requiring advanced materials and technologies are essential.

Our advanced materials, categorized into heat, electricity, light, magnetism, and nanotechnology are essential for a wide range of applications.

Click the icons to explore the detailed explanations of each functionality.

Exploring the Possibilities of Heat Control

Exploring the Possibilities of Heat Control

- # Efficient Heat Dissipation for Devices

- # Low-Temperature Powder Sintering

- # High-Temperature Usability

- # Low-Temperature Processes

- # Increased Design Flexibility

Thermal Conductivity

Disperses heat quickly to prevent overheating.

Heat Dissipation

Stable operation even in harsh temperature.

Low-Temperature Sintering

Saves energy and reduces thermal load.

Electronic components, especially semiconductors, are sensitive to high temperatures. If the temperature exceeds a certain level, the risk of malfunction increases. With the miniaturization of devices, the advancement of IoT, and enhanced performance, effective heat management has become crucial. Our materials with excellent thermal conductivity quickly disperse internal heat, ensuring stable operation and preventing local overheating.

Additionally, our low-temperature sintering technology bonds particles at lower temperatures, reducing thermal load on surrounding materials. This increases material options, design flexibility, and reliability, while also contributing to energy conservation and CO2 emission reduction. Our offerings include materials with thermal conductivity, heat dissipation, heat resistance, and low-temperature sintering, supporting efficient thermal management and enhancing reliability in high-temperature environments.

Exploring the Possibilities of Light

Exploring the Possibilities of Light

- # Absorbing Near-Infrared Rays

- # Converting Light to Heat

- # High Transparency Materials Utilizing Light Energy

- # Taking in Necessary Light

NIR Absorption

Selective Absorption near-infrared rays.

Transparency

High transparency with retaining pigment color.

Photothermal Conversion

Conversion of absorbed near-infrared rays into heat.

Solar light includes visible and near-infrared rays. Our near-infrared absorbing materials efficiently absorb specific wavelengths and convert them into heat. For example, clothing made of fabric using these materials generates instant warmth by absorbing not rays. They can also be applied to window glass and agricultural nets to let in needed light while blocking excess heat, and for bonding transparent resins. With high photothermal conversion efficiency, these materials enhance comfort in buildings and vehicles and help reduce energy consumption.

Exploring the Possibilities of Electricity Control

Exploring the Possibilities of Electricity Control

- # Materials That Conduct Electricity Easily

- # High Electrical Conductivity

- # Insulating Materials Next-Generation Communication Technology

- # Smoothness

- # Low Loss of High-Frequency Signals

Conductivity

Enables efficient current flow with minimal loss.

Insulation

Achieves high insulation reliability on circuit boards.

High-Frequency Characteristic

Minimizes high-frequency signal loss.

The precision of electronic devices has advanced, making efficient electrical conductivity crucial for stable operation. In addition to conductivity, insulation in resistors and substrates is critical. With the rise of large-capacity, high-speed data communication, materials with high-frequency characteristics are needed. Conductive materials like gold, silver, and copper minimize power loss, enhancing the performance of electronic devices. As IoT accelerates and 5G technology expands, high-speed, large-capacity communication is possible using millimeter waves. This requires insulation materials with low dielectric loss to prevent signal degradation. Dielectric loss occurs when energy is lost as heat in a dielectric material under an AC electric field. Thus, materials with low dielectric loss are essential.

Exploring the Possibilities of Magnetism

Exploring the Possibilities of Magnetism

- # High Magnetic Materials

- # High Magnetic Properties

- # Magnetostrictive Materials

Magnetic Enhancement

Strong magnetism for energy conversion.

Magnetic Properties

High performance with excellent magnetic properties.

Magnetostrictive Effect

Utilizes shape changes induced by magnetism for power generation.

Magnetic energy is used in electric motors, generators, and magnetic recording devices. To utilize this energy effectively, materials with excellent magnetic properties are required. Magnetic materials, such as permanent magnets or electromagnets, generate and retain magnetic fields, enabling efficient energy conversion in devices like motors, speakers, and sensors. Rare-earth magnets are known for their high magnetic force and durability, improving the performance and miniaturization of motors and generators, and reducing energy consumption.

Magnetostrictive materials, which change shape under a magnetic field, are used in actuators and sensors for precise position control and high sensitivity detection. This magnetostrictive effect is crucial for these applications.

Exploring the Possibilities of Chemistry

Exploring the Possibilities of Chemistry

- # Fine Processing and High-Performance Materials

- # Reducing Additive Amounts with High Functionality

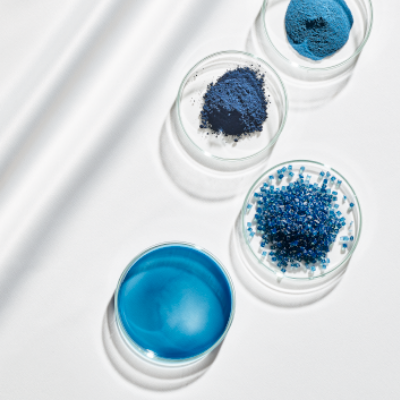

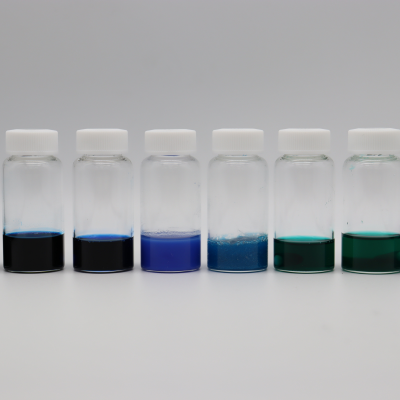

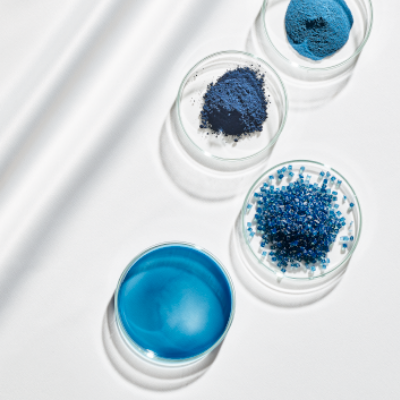

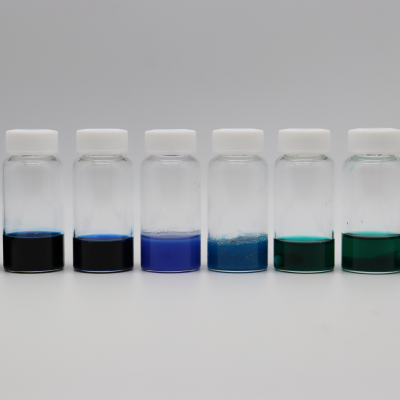

Dispersion

Uniform dispersion maximizes properties.

Microfabrication Capability

Enhances durability and adhesion for diverse applications.

Chemical Resistance

Withstands harsh high-temperature alkaline solutions.

By leveraging the microstructure, characteristics, and energy of materials, we enhance their functional properties and improve product performance. Our dispersion technology for powder materials is key, expanding material capabilities by achieving uniform particle distribution through controlled interactions. Our products have sharp particle size distributions due to high dispersion technology, which also enhances chemical resistance.

Chemical Resistance: Our materials maintain performance even in harsh chemical environments, such as high-temperature alkaline solutions, outperforming organic materials. They also perform well with reduced additives, conserving resources and broadening application scope.

Microfabrication Capability: Improves flexibility and adhesion on substrates, expanding the range of applications beyond conventional methods.