Article

閉じる

Search

Excellent oxidation

resistance enables

handling in air.

Superior low-temperature sintering,

starting around 200℃*

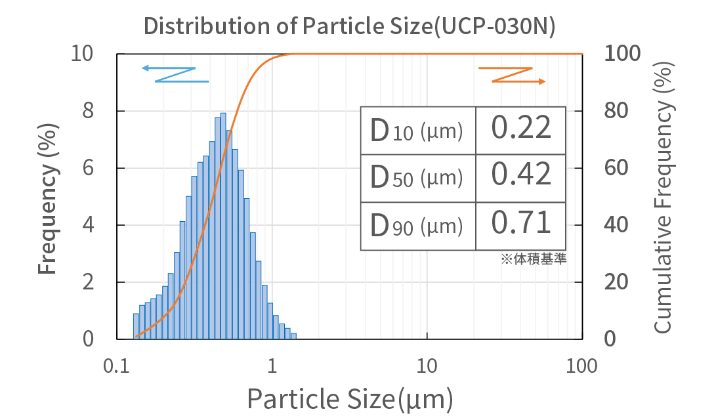

Sharp particle size

distribution-High

Monodispersity**

Offering a Range of

Fine Particle lineup

*Note: Despite its fine particle size, the powder features an organic coating on the surface that ensures very slow oxidation at temperatures ranging from room temperature to below 160°C. This results in excellent stability during storage and easy handling, and it can also be managed in the atmosphere at temperatures below 160°C.

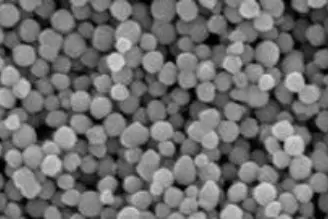

**Note: Our unique wet process powder control technology achieves sharp particle size distribution and high monodispersity. Composed of nearly 99% copper, it allows for the formation of dense sintered surfaces with minimal impurities at low temperatures.

Sumitomo Metal Mining’s fine copper powder (UCP series) has a uniform particle size distribution, allowing low-temperature sintering by bonding particles at temperatures significantly lower than the copper melting point. The unique surface treatment of our copper powder with an organic coating provides it with oxidation resistance, allowing it to be handled in the atmosphere at temperatures ranging from room temperature to 160°C. There is increasing demand for copper powders that can sinter at temperatures suitable for components with low heat resistance, such as resin substrates.

Generally, lowering the sintering temperature of metal particles can be achieved by making the particles finer. However, for copper powders, fine particles tend to oxidize easily, making handling more difficult.

Sumitomo Metal Mining has developed copper powders with particle sizes of 200nm, 300nm, and 400nm that achieve both ease of handling and low-temperature sintering using the wet synthesis techniques cultivated over many years.

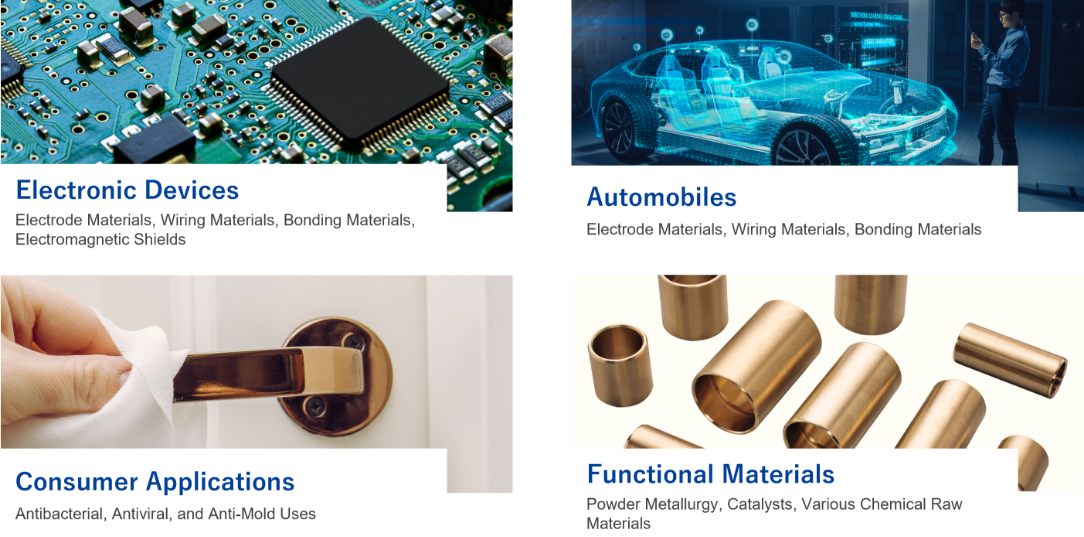

By offering a lineup of fine particle sizes, we aim to speed up customer development. Additionally, leveraging the unique properties of fine particles, we can enhance performance not only in the field of electronic materials but also in applications such as antibacterial materials.

Sumitomo Metal Mining’s fine copper powder development product series. If your requirements are not listed, please feel free to contact us.

| Developed Product lineup | UCP-040N | UCP-030N | UCP-020N | UCP-020N2 |

|---|---|---|---|---|

| SEM Average particle size(μm) | 0.44 | 0.26 | 0.21 | 0.21 |

| O(%) | 0.32 | 0.37 | 0.57 | 0.70 |

| C(%) | 0.20 | 0.26 | 0.38 | 0.53 |

*The average SEM particle size is representative.

Anticipated applications: conductive materials, electromagnetic shielding materials, conductive fillers, antibacterial materials.

For more details, please download for detailed product information, including specifications.

Click below to access.

Overview of UCP series

Applications include paste production, ink production, additives, incorporation and powder metallurgy into various materials.

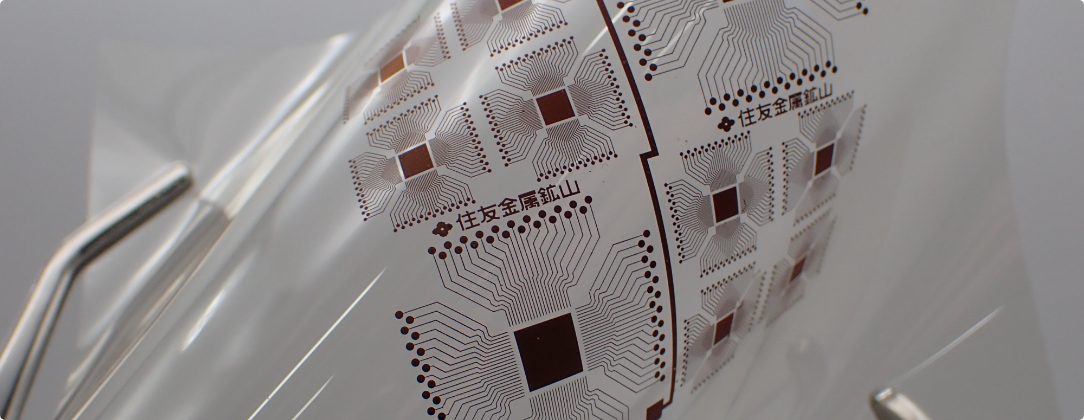

Oxidation-resistant copper circuits on transparent polyimide substrates using our fine copper powder

Forming copper electrodes involves numerous challenges such as aggregation measures, lowering sintering temperatures, and maintaining quality (oxidation resistance).

Sumitomo Metal Mining’s fine copper powder (UCP series) starts sintering at lower temperatures compared to atomized copper powders, depending on factors such as the environment and other sintering conditions.

Therefore, it can be used alone or as a sintering aid to lower the sintering temperature of other copper powders.

Furthermore, due to special surface treatment, our fine copper powder retains excellent oxidation resistance despite being fine particles.

This enhances the dispersion in organic solvents and the stability (oxidation resistance) of the paste. If you face challenges in creating smooth, thin copper electrode films using fine copper powder, please consider our fine copper powder.

ombining Sumitomo Metal Mining’s expertise with industry insights, X-MINING is here to innovate and solve challenges.

If you see potential, don’t hesitate to reach out with any questions you may have!

Article

X-TALK

X-TALK

X-TALK

Case

Article

Introducing Sumitomo Metal Mining’s material products,

which are the starting point for X-MINING innovation.