Fine Copper

Powders

【R&D】

閉じる

Search

As we move into a world where everything is connected—the era of the Internet of Things (IoT)—the wearable device market continues to grow. Wearables are making their way into healthcare and everyday life, and we are starting to see the development of new devices beyond smart glasses and smartwatches.

One of the most important factors for creating competitive devices is innovation in materials technology. For wearable devices, especially, it is essential to make electronic parts lighter, thinner, and smaller, which requires significant progress in material science.

In this context, “fine copper powder” has recently gained significant attention. This advanced material supports the evolution of wearable devices by enabling greater flexibility and single-use options, increasing the practicality of wearables.

In this article, we will introduce the potential of fine copper powder, especially our “UCP Series,” for next-generation wearables and semiconductors.

▼ Click here for more information about “X-MINING.”

With rapid advancements in IT and electronics, the scope of wearables is expanding beyond traditional watches and glasses to include patches attached to the skin, and even clothing and accessories.

These wearable devices are already being applied in a variety of areas, such as healthcare, sports, nursing care, and safety management.

For example, wearable health monitors can continuously track vital signs, providing real-time information for both users and healthcare professionals. Smart sports gear can measure physical performance and offer personalized feedback.

As wearables become more widespread, there is increasing demand for devices that are lightweight, comfortable, and unobtrusive in everyday life.

Fine copper powder can be used in a variety of wearable applications, such as:

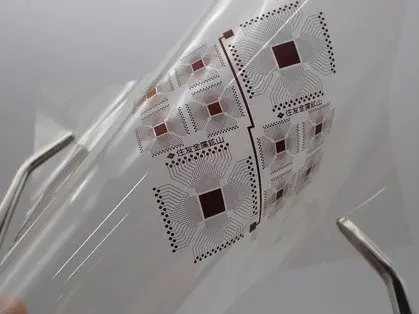

The ability to print electronic circuits onto flexible materials is opening up new possibilities for design and functionality in wearables.

For wearables to become a seamless part of daily life, devices must be as lightweight and comfortable as possible. There is also a need for flexibility so that devices can conform to the body, and for disposability, which is important for hygiene and convenience—especially in healthcare settings.

This means that not only device design but also the materials used are under the spotlight. Innovation in materials is essential for making wearable devices that are thin, light, and flexible.

There are still many technical hurdles to overcome before wearables can reach their full potential. These include:

To address these challenges, the development of new materials with excellent electrical properties and processability is essential.

Copper is a metal with excellent electrical conductivity, second only to silver, and is widely used in electronic devices.

Fine copper powder, made by refining copper into microscopic particles, offers several advantages:

Because of these properties, fine copper powder is gaining attention as a key material for next-generation wearable devices and printed electronics.

Our company has developed the UCP Series, a range of ultra-fine copper powders optimized for flexible and printed electronics applications.

Key features of the UCP Series include:

These features make the UCP Series ideal for forming flexible circuits and electrodes, supporting the next generation of wearable devices.

For more information, please see the “Fine Copper Powder Product Page” in our website.

We believe that open innovation and collaboration are essential for realizing the full potential of fine copper powder. By working together with companies that specialize in process technologies—such as MOD paste formulation, printed electronics, and circuit formation—as well as medical device manufacturers, we aim to develop practical and marketable products using fine copper powder.

Collaboration is not limited to companies; partnerships with academic institutions are also extremely important. Moving forward, we want to expand these efforts and work with a wider range of partners to explore new possibilities for fine copper powder.

[Product Introduction] MOD Paste (Metal Organic Decomposition Paste)

Copper is more cost-effective than silver and offers a variety of useful properties. By expanding the use of copper-based materials, we hope to enable the production of diverse devices at lower costs, which can help address global societal challenges. Our UCP Series supports the realization of these goals.

If you have ideas for new developments or business collaborations, please contact us through X-MINING.

Together, let's create new possibilities for copper.

Written by: X-MINING Editorial Team

Ready to get started? Contact us to talk about your requirements.

Introducing Sumitomo Metal Mining’s material products,

which are the starting point for X-MINING innovation.