Article

閉じる

Search

Increased Density with

1/50 Conventional

Particle Size for Cost Savings

Wear Prevention

and Cost Reduction with

µ-Sized Fine Powders

Injection Molding with SmFeN and Ferrite:

Enhance Magnetism & Reduce Process Steps

Neodymium-Free:

Reducing Inventory Risks from Price Changes

*Note: These are insights based on comparisons between our SmFeN products and Nd products. For more details, please contact us.

Sumitomo Metal Mining’s Wellmax™︎ Samarium Iron Nitrogen (SmFeN) magnetic materials, have been manufactured for over 20 years. These materials use Samarium (Sm), an excess element among the 17 rare earth elements, and provide a stable price compared to Neodymium Iron Boron (NdFeB) magnet materials.

Anisotropic magnet materials typically have variable properties based on factors like magnetic circuit design and molding conditions, making them seem difficult to use, but we support product realization with services such as magnetic field analysis simulations and molding advice.

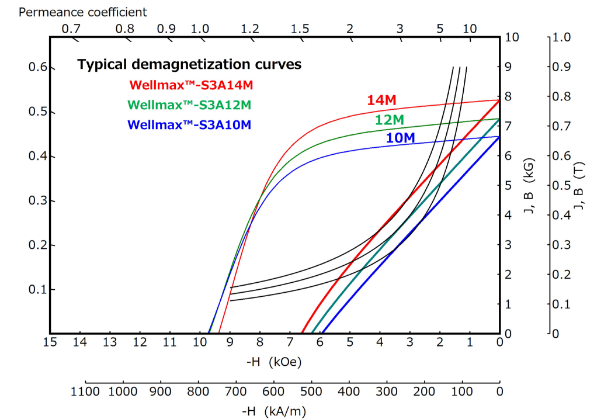

This graph shows typical demagnetization curves comparing the magnetic properties of our products Wellmax™ series.

If the product you are looking for is not in our lineup, please feel free to contact us.

| Product name | Magnetic Powder | Binder | Max. Magnetic Energy Product (kJ/m3(MGOe) Features | Characteristics |

| S1 | SmFeN

(Anisotropy) |

(Magnetic Powder) | 286~310(36~39) |

・Average particle size 2~3μm diameter SFN fine particles

|

| S3 | PA12 | 80~111(10~14) |

|

|

| S4 | SmFeN+Ferrite

(Anisotropy) |

PA12 | 24~56(3~7) |

|

| S5P | SmFeN+NdFeB

(Anisotropy) |

PPS | 80~103(10~13) |

|

|

||||

For more details, please download for detailed product information, including specifications in each lineup.

Click below to access.

Bonded Magnet Materials of SMM

Anisotropic SmFeN (Samarium-Iron-Nitrogen) magnet powder

Anisotoripic SmFeN (Samarium-Iron-Nitrogen) PA12 magnet pellet for injection molding

Anisotropic SmFeN (Samarium-Iron-Nitrogen) mixed Ferrite PA12 magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PPS magnet pellet for injection molding

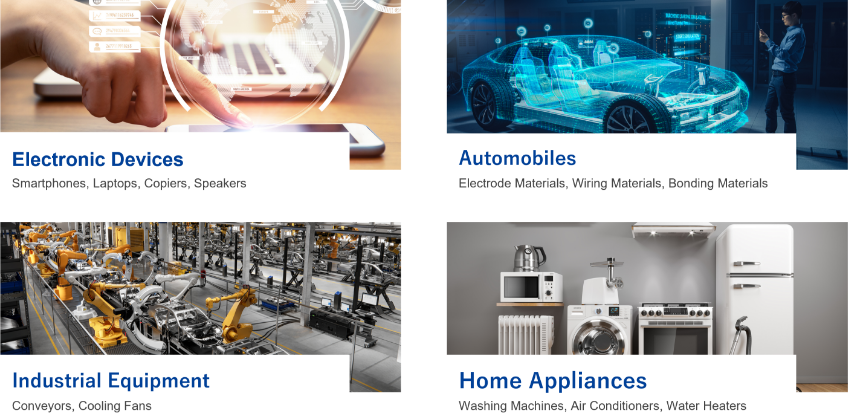

Magnets are a core part of motors, and their strength significantly impacts output and energy efficiency.

Wellmax™ SmFeN magnetic materials have more than 20 years of experience in familiar electric appliances such as air conditioners and washing machines. In recent years, there has been an increase in the use of motors in various applications, including automotive motors.

Sm is one of the 17 rare-earth elements and has a smaller deposit than Neodymium (Nd) but more than Dysprosium (Dy). The most popular material used with Sm is cobalt (SmCo).

While demand for Nd (neodymium) and Dy (dysprosium) is increasing, demand for Sm continues to be small.

Therefore, use of Sm leads to the efficient use of global resources.

When Nd and Dy are mined, Sm is also mined together with other rare-earth elements, so it remains an excess element in the process of obtaining Nd and Dy. Therefore, the use of Sm is expected to lead to the efficient use of global resources.

About the surge in the price of rare-earth magnets.

Magnetic Material Applications Such as EV Motors, and the Potential of Samarium-Iron-Nitrogen Magnetic Materials

We provide magnetic field analysis simulations for magnet mold design so that our customers can effectively use anisotropic magnets and ensure that their products meet the required performance. We also provide advice on mold configurations to support the realization of our customers’ products. Examples include the use of magnetic and non-magnetic materials, magnet-related equipment (molding machines, magnetizing power supplies, etc.), and molding conditions.

Support for mold design with our simulation of magnetic field analysis

Support for mold design with our simulation of magnetic field analysis

ombining Sumitomo Metal Mining’s expertise with industry insights, X-MINING is here to innovate and solve challenges.

If you see potential, don’t hesitate to reach out with any questions you may have!

Article

X-TALK

X-TALK

Case

Case

Case

Introducing Sumitomo Metal Mining’s material products,

which are the starting point for X-MINING innovation.