Magnetic

Materials

閉じる

Search

Anisotropic magnet material exhibits the magnetic properties shown in the catalog by adding an orientation magnetic field when making the magnet to align the magnetization in the direction of interest.

Proper adjustment of the strength and direction of the aligning magnetic field (hereinafter, orientation design) is a very important factor in the use of anisotropic magnetic materials. Orientation design can greatly change the characteristics of the magnet and the waveform of the surface magnetic flux.

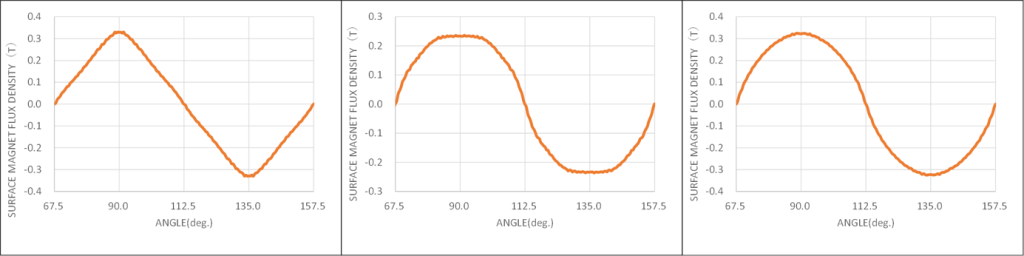

Figure 1 shows the simulation results showing that the waveform of the surface magnetic flux density changes depending on the orientation design even if the shape and material are the same.

Fig. 1 Waveform example of surface magnetic flux density (same shape and same material)

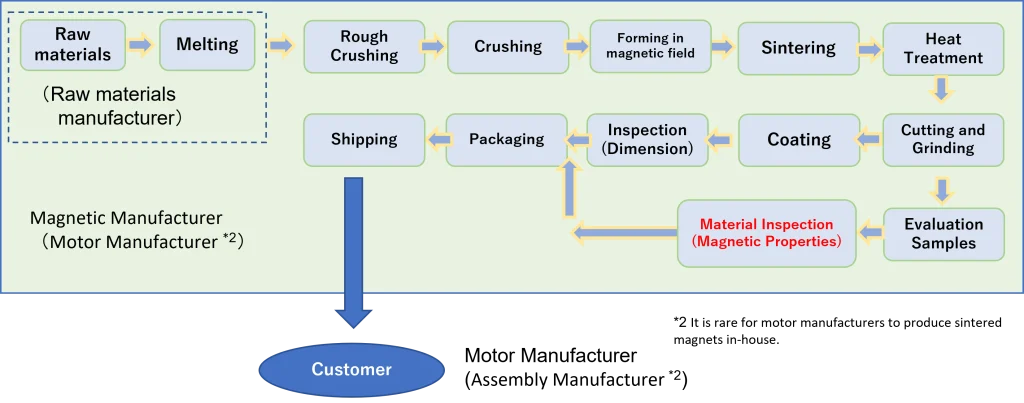

In many cases, manufactures of anisotropic sintered magnet design the orientation and shape of magnet. It means users of magnet do not need to design of magnet orientation. (Fig. 2).

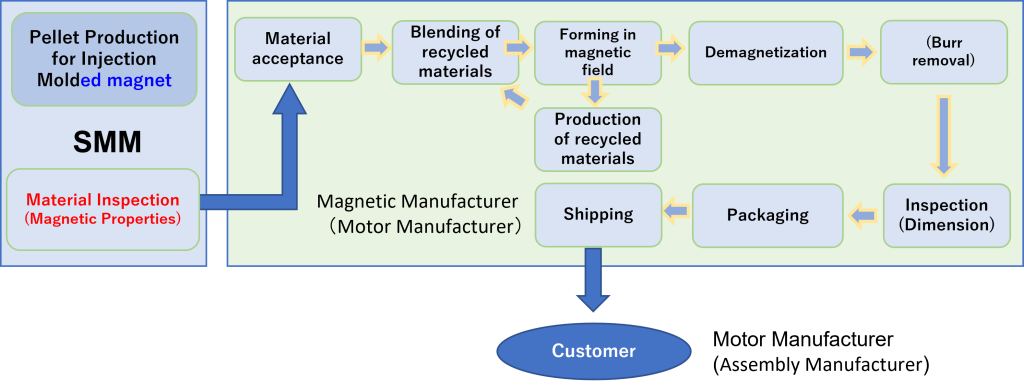

In contrast, the molder of anisotropic injection-molded bonded magnets need the orientation design of it. In case of this, the molder is a manufacture of magnet or user of magnet or both (Fig. 3).

Fig.2 Flow of Anisotropic Sintered Magnet Processing

Motor manufacturers purchase and use processed products that meet the magnetic specification standards of magnet manufacturers (such as residual magnetic flux density and maximum magnetic energy product).

Fig.3 Flow of Anisotropic Injection Molding Magnet Processing

Material manufacturers ( (such as SMM) sell materials (anisotropic injection-molded magnetic materials) as products based on standards by measuring magnetic properties with shaped samples molded under certain conditions.

Material manufacturers (such as MHI) sell materials (anisotropic injection-molded magnetic materials) as products based on standards by measuring magnetic properties with shaped samples molded under certain conditions.

On the other hand, motor manufacturers will (buy) use molded products that conform to the characteristic standards (e.g. surface magnetic flux density) of the molded magnets. Therefore, it is very important for customers to use materials in the process of manufacturing molded products, such as orientation and molding conditions.

Typically, the orientation and shape of anisotropic sintered magnets are designed by the manufacturers. Thus, the users of magnets do not need to design magnet orientation.

In contrast, anisotropic injection-molded bonded magnets are typically designed by the molding company. Thus, the molding company will require training and assistance in orientation and design of the magnet.

On the other hand, you can hardly know the orientation design of anisotropic injection molded bonded magnets based only on the results of dimensions and surface magnetic flux density.

It means, unlike sintered magnets, molding companies can better conceal the originality of their orientation designs.

Therefore, unlike sintered magnets, you can more likely sustain the originality of your applications if the concealment property of the orientation design can be kept. In addition, you can design your application with magnets that not only have simply ring shapes but also have shapes with other parts.

Anisotropic ferrite injection magnets are used for many applications because they are inexpensive.

To design more powerful applications of anisotropic rare earth bonded magnet materials, you need to know how to design the orientation of magnets for each material.

We offer support for magnetic orientation design using magnetic field analysis simulation.

This will reduce initial development costs and lead to the realization of your short-term goals in the development of your products.

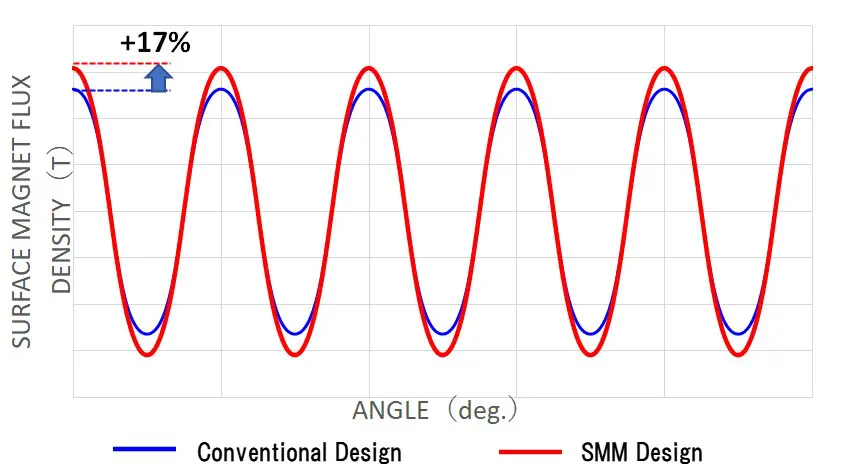

Fig. 4 shows a simulated magnetic field analysis of the surface magnetic flux density of magnets molded using Wellmax™.

Fig. 4: Example of simulation of magnetic field analysis (comparison with conventional design)

You can see that SMM design based on our simulation using magnetic field analysis will expect to obtain high characteristic than conventional design even for the same material.

Please feel free to contact us if you are interested in design support by magnetic field analysis simulation of SMM.

View details about Sumitomo Metal Mining’s Magnetic materials

We support our customer's product development by using magnetic field analysis software,

aiming to shorten development time and reduce cost.

Ready to get started? Contact us to talk about your requirements.

Introducing Sumitomo Metal Mining’s material products,

which are the starting point for X-MINING innovation.