Article

閉じる

Search

Ultra-Fine Powders

Below 0.1µm with

Proprietary Wet Synthesis Technology

Uniform Particle Size

Distribution

in Ultra-Fine Powder

Low Inorganic

Impurities from Organic Materials

Smooth, Spherical

Particles with Minimal

Surface Roughness

*Note: These values provided are representative of our development products. For more specific product details, please contact us.

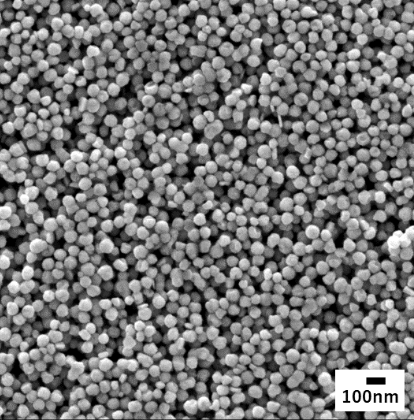

Developed ultra-fine nickel powder less than 0.1 microns using unique wet synthesis technology cultivated over many years. Despite being fine particles, it has uniform particle size distribution and excellent dispersibility. Additionally, it has low impurities and minimal presence of organic-derived impurities typically seen in products from the wet process, making it suitable for various electronic components.

If the product you are looking for is not in our lineup, please feel free to contact us

| Typical value | Developed product name:(MIT-60) | Developed product name:(MIT-100) |

|---|---|---|

| SEM particle size (nm) | 60 nm | 100 nm |

| Specific surface area (㎡/g) | 14 to 16 ㎡/g | 9 to 11 ㎡/g |

| O(wt%) | 2.5 to 3.0 wt% | 1.8 to 2.2 wt% |

| C(wt%) | 0.15 to 0.25 wt% | 0.1 to 0.15 wt% |

For more details, please download for detailed product information, including specifications.

Click below to access.

MIT-60, MIT-100

Our nickel powders have spherical shape and smooth surface and there are few agglomerated or consolidated particles in them. These features make them suitable for use in various functional inks, slurries, and pastes.

The following applications are expected:

Wet synthesis is a particle synthesis process involving chemical reactions in water or other solutions. It is used for synthesizing various materials such as nanoparticles, metal complexes, and oxides. Our ultra-fine nickel powder is produced via wet synthesis and has a uniform particle size distribution. For more details about the wet synthesis process, please see the column “What is Crystallization?” as following.

Crystallization Used for Metal Powder Manufacturing|X-MINING|Sumitomo Metal Mining

ombining Sumitomo Metal Mining’s expertise with industry insights, X-MINING is here to innovate and solve challenges.

If you see potential, don’t hesitate to reach out with any questions you may have!

Introducing Sumitomo Metal Mining’s material products,

which are the starting point for X-MINING innovation.