Article

閉じる

Search

Particle Shape:

0.2 to 1.0µm

Average Particle Size with

Sharp Distribution

Crystallinity:

Well-Crystallized

Aggregates Ranging from a

Few nm to Tens of nm

Surface Treatment:

Special surface coating

providing electrical insulation

and oxidation resistance

Magnetic Properties Adjustment:

Optimizable Magnetic

Properties and High

Saturation Flux Density

*Note: These values are representative of our development products. For more specific product details, please inquire.

*Particularly for applications in soft magnetic materials.

・Customization:Composition ratio, particle size, and surface treatment can be adjusted to meet customer requirements

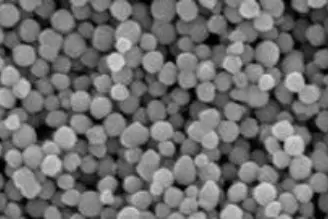

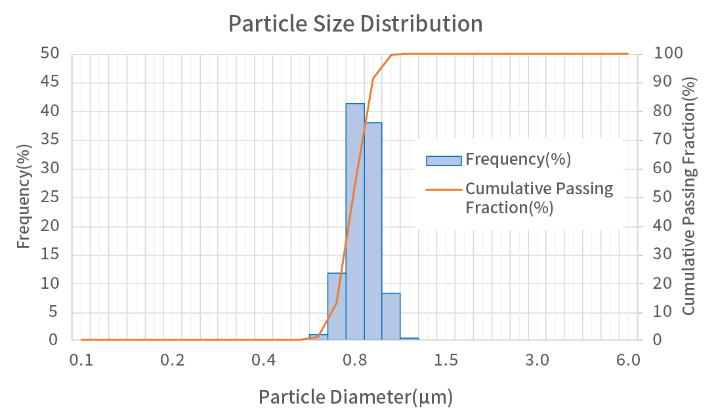

・Particle Shape:Average particle diameter of 0.2 to 1.0μm with a sharp particle size distribution

・Crystallinity:Aggregates of micro-crystals ranging from a few nanometers to tens of nanometers

・Surface Treatment:Special surface coating providing electrical insulation and oxidation resistance

・Magnetic Properties Adjustment:Magnetic properties can be optimized according to the needs by adjusting the composition. Especially notable for its high saturation magnetic flux density (Bs) in soft magnetic material applications

Composition ratio, particle size, and surface treatment can be customized according to customer requirements, please feel free to contact us. Below are reference values for soft magnetic material applications. Composition ratio, particle size, and particle shape can be adjusted to meet specific needs.

| Composition | Iron-based alloys (e.g., iron nickel (Fe-Ni), iron cobalt (Fe-Co), iron nickel cobalt (Fe-Ni-Co)) |

|---|---|

| Particle shape | Spherical particle |

| Saturation magnetic flux density (Bs) | 1.2 – 2.0T (adjustable arbitrarily according to the components) |

| Mean particle diameter | 0.2-1.0μm |

| Surface coating | Allows insulation coating on the surface |

Our Iron-Nickel-Cobalt Alloy Fine Powders utilize their properties for the following potential applications:

There are various methods to produce metal powders, such as atomization, spray pyrolysis, PVD, wet synthesis, carbonate process, but our Iron-Nickel-Cobalt Alloy Fine Powder is produced via wet precipitation. Wet precipitation is a safe and low-energy consumption manufacturing process.

Detailed information on the wet synthesis method “What is crystallization?”

ombining Sumitomo Metal Mining’s expertise with industry insights, X-MINING is here to innovate and solve challenges.

If you see potential, don’t hesitate to reach out with any questions you may have!

Introducing Sumitomo Metal Mining’s material products,

which are the starting point for X-MINING innovation.