Magnetic

Materials

閉じる

Search

=Customer’s requirements =

“Because of the abrasion, you have to externally carry out maintenance and parts replacement and start up every time…”

“If you use the carbide steel, you can reduce the frequency of mold maintenance. However, carbide steel is expensive and easy to broken for a slight shock, you are afraid to use it for mold parts…”

“If you do an abrasion protect coating, you can reduce the frequency of mold maintenance, too. However, coating cause a contamination due to peeling, you are afraid to use the coating parts…”

“You want to prevent the abrasion of molds without lowering the magnetic force, but you don’t know a good magnet material…”

Isotropic NdFeB (neodymium iron boron) magnet powder is a large hard powder around 100μm produced by the ultra-quench method, so that the powder shaves the mold surfaces with the high-pressure flow during injection, and then roughness further causes the abrasion of molds.

Sumitomo Metal Mining’s products (Wellmax™-S1/S3/S4) consisting of SmFeN (samarium iron-nitrogen) are 2-3μm magnet alloy powder or the injection compound used this powder.

Wellmax™-S3/S4 features 24kJ/m³ (2MGOe) of ferrite bond magnetic or higher, and 111 kJ/m³ (14MGOe) of isometric NdFeB bond magnetic or higher. In addition, SmFeN magnet materials do not contain rare earth elements, such as neodymium (Nd) and dysprosium (Dy), which are concerned about supplies.

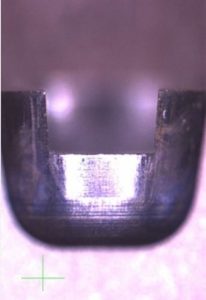

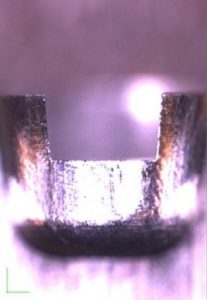

【Cross section figure of gate mold parts】Parts material: HPM75(HRC40)

(before shot)

(after 1,000 shots)

From the left figure, SmFeN, ferrite, isometric NdFeB injection molding material

/Significant abrasion is found in the isotropic NdFeB.

Wellmax™ magnet materials can be used with isotropic properties, however, for higher properties, anisotropic magnets must be made by configuring a dedicated magnetic circuit in the mold.

With a wealth of knowledge and experience, Sumitomo Metal Mining provides support for magnetic design with particle alignment and the production of our customers’ original magnetic products.

The functions of Wellmax™, such as to prevent abrasion of molds and reduce raw material risk, can be applied to other fields.

Do you want to realize your imagination with our Wellmax™?

Bonded Magnet Materials of SMM

Anisotropic SmFeN (Samarium-Iron-Nitrogen) magnet powder

Anisotoripic SmFeN (Samarium-Iron-Nitrogen) PA12 magnet pellet for injection molding

Anisotropic SmFeN (Samarium-Iron-Nitrogen) mixed Ferrite PA12 magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PPS magnet pellet for injection molding

Ready to get started? Contact us to talk about your requirements.

Introducing Sumitomo Metal Mining’s material products,

which are the starting point for X-MINING innovation.